Project Description

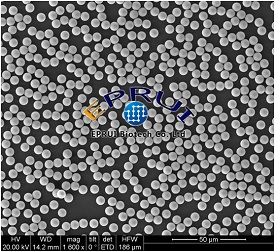

Silica spacer is widely used for frame gap control, as well as cell gap control for special applications. EPRUI supplies silica spacers with perfect spherical morphology, precisely controlled particle size, narrow particle size distribution, excellent resistance against heat, cold and chemicals and great mechanical strength and superior crush resistance.

EPRUI supplies two types of high quality silica spacers: Si and SiS.

Our Si type is mainly used as side spacer while SiS series is used to control cell thickness inside.

Physical Data

| Specification | Result | Test Method |

|---|---|---|

| Mean Diameter | ±0.05um | Coulter Counter |

| CV. % | <3% | Coulter Counter |

| 10% Modulus of elasticity | >4000 kgf/mm2 | Shimadzu MCT210 |

| Density | 2.1 g/cm3 | Multi Volume Density Test |

| Refractive Index | 1.46 | 20℃ λ=589nm |

| Thermal Decomposition Temperature | >2200℃ in air | / |

| Volatile Components | <1% | 105℃*1hr |

Product List

| Type | Product | CV | Diameter | Application |

|---|---|---|---|---|

| Si | EPRUI-SSi | <3.5% | 2.0-20.0um | Side Spacer |

| SiS | EPRUI-SSiS | <3% | 2.0-20.0um | TN,STN |

Recommended

Recommended Spraying Methods

- EPRUI-SSi type silica spacer is used as side spacer, it can be mixed directly with other ingredients

- In case of cell gap applications, EPRUI-SSiS silica spacers can be either dry or wet sprayed

- Dry Spray : in order to get best effect, it is recommended to vacuum dry silica spacers at 80 °C for 8 hrs (caps off) before dry spraying, which ensures spacer microspheres disperse smoothly and freely

- Wet Spray: Disperse the silica spacers in organic solvent such as isopropanol or ethanol, ultrasonicate a while before adding proper amount of water. This usually works better than dispersing the microbeads directly in aqueous solution containing of organic solvent

Recommended Spraying Density

| Silica LCD Spacers | TN | STN |

|---|---|---|

| Spraying Density | 40-100 particles/mm2 | 80-200 particles/mm2 |

Packing & Storage

- 10g or 20g glass vials with plastic caps and inserts to keep moisture away from the contents. PET vials of 10 g or 20 g are also available upon request.

- The label on the vial includes product name, lot number, expiration date, weight, RoHS, inspection passing stamp, etc.

- The vials should be stored in dehumidifying cabinets with controlled temperature and humidity. The cabinet should be set at room temperature and kept under 25% humidity.

It is recommended to use up the entire product in a vial once it is opened.